| MOQ | 50K–100K |

|---|---|

| Size | 50*70mm(Min) 350*600mm(Max) |

| Material | BOPP/PET+PET/PETAL/Kraft Paper/+LLDPE/CPP |

| Thickness | 50Mircons-120Mircons (2Mil-5Mil) |

| Function | Punch Hole, Handle, Metallized |

| Printing | D-Met Printing, Vanishing, Matte Finishing, Stamping |

| Products | Normal Material Use |

| Chips | BOPP/CPPAL,BOPP/PETAL/CPP |

| Noodles | BOPP/PE,PET/PE,BOPP/CPP |

| Candy | BOPP/CPP,PET/PE |

| Frozen Foods | BOPP/PE,BOPP/CPP |

| Industry | Products Use |

| Dry food | Snack bars, Nuts, Cookies, Biscuits, Macaron, Sandwich cake |

| Inflatable food | Potato chips, Potato crisps, Snack chips, Fried chips, Fried chicken bar |

| Confectionery | Jawbreaker, Gummy, Hard Candy, Lollipop, Chocolate bar, Gum, Rainbow Candy, Sandwich candy, Fruit powder sugar |

| Others | Noodles, Frozen dumplings, Pizza, Spices, Seafood |

Vacuum bag

Vacuum bag: in the packaging process, the air inside the packaging bag is discharged out by vacuum sealing machine or air extracting pump, which can inhibit the reproduction of bacteria and other microorganisms and prolong the storage period.

Type of vacuum bags: LIBOPACK focuses on the production of food vacuum bags. We produce the embossed vacuum bags and non-embossed vacuum bags.

Advantages of food vacuum bag:

1.Moisture proof, mildew proof, pollution proof and oxidation proof.

2.Volume saving: since the air inside the packaging bag is discharged, the packaging volume and storage space are saved.

3.Save transportation cost: the volume of packaging is minimized, and the loading capacity of goods will be more, saving transportation cost.

4.Extended storage period: the air inside the packaging bag is discharged, and the external air is blocked by the packaging materials, so the shelf life of food is extended.

LIBOPACK specializes in the production of food vacuum packaging bags. We emphatically promise that the materials used are food grade and BPA free. In order to meet the needs of customers, we can provide the relevant test reports.

Flexible packaging roll films

Fin seal pouch & bag

3 side seal pouch & bag

Gusset pouch & bag

Stand up bag & pouch

Shaped bag & pouch

Spout pouch & bag

Flat bottom bag & pouch

By the way. LIBOPACK has HP 20000 digital printing press, which can print plastic, paper and other materials, with a daily output of 50000-80000pcs.

Please contact us immediately, we will quote within 8 hours.

Different kind of styles pouch for choice :Stand up pouch with zipper /Quad seal Pouch with value /Middle seal Pouch/Auto-Packaging plastic roll film/Kraft paper aluminum foil pouch etc .

Vacuum Bags —frequently asked questions you are most concerned about:

1、what is a vacuum bag ?

Vacuum bag, also known as decompression packaging, is to pull out all the air in the packaging container seal, maintain the bag in a high decompression state, air scarce is equivalent to the effect of low oxygen, so that microorganisms have no living conditions, in order to achieve the purpose of fresh fruit, no disease and rot.

2、2、What is a food vacuum bag?

As the name suggests, it is a vacuum bag for packaging food. The materials used (including ink and glue) are food grade and BPA free.

3、What materials are food vacuum bags made of?

PET, PA (NY), AL、PE and RCPP. they are high barrier and low temperature resistant materials. Among them, PA and AL play a barrier role, and PE is heat sealing material.

4、What are the production processes of vacuum bags?

There are embossed vacuum bags and non-embossed vacuum bags. Now commonly used food vacuum bags, most of them are embossed vacuum bags, because after embossing, the friction coefficient increases, the content is not easy to slide, can improve the work efficiency. At the same time, the embossing is conducive to the discharge of air in the bag.

5、What foods are vacuum bags suitable for packaging?

Meat products, cooked food, snacks, rice, various grains, dried fruits, vegetables, and coffee beans, tea, etc.

6、Can food vacuum bags be recycled?

Certainly. Because the materials used are relatively single, the value of recycling will be relatively high.

7、What is the size of food vacuum roll film?

Take the home use as an example: generally 5m / roll and 10m / roll.

8、How to use food vacuum bag correctly?

8.1. First of all, pay attention to the heat sealing of food vacuum packaging bags. Do not stick oil, protein, food and other residues in the sealing part, and ensure that the sealing can be completely heat sealed.

8.2. When heating and sterilizing vacuum packaging bags, sterilization temperature and time should be strictly controlled to avoid excessive pressure in the packaging bags due to high temperature, which may lead to the separation and rupture of the packaging bags.

8.3. The vacuum packaging bag of food must be completely vacuumized, especially the vacuum packaging of raw meat and amorphous food, and no residual gas is allowed to prevent residual gas from causing food spoilage in the vacuum packaging bag.

8.4. The products unsuitable for food vacuum packaging are fragile foods. If these foods have edges and corners, they are easy to puncture and penetrate the packaging bag. Therefore, it is better not to use vacuum packaging for this kind of food, but other packaging, such as gas filled vacuum packaging bag.

8.5. Bones in meat products also have hard edges and corners, and are not suitable for vacuum packaging.

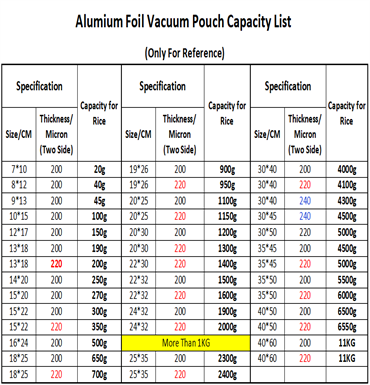

9、What are the packaging specifications of vacuum bags?

10、Does LIBOPACK have a stock of vacuum food bags?

Yes, LIBOPACK has a long-term inventory of vacuum bags of various structures and sizes. These vacuum bags are not printed.

11、Can we get free samples?

Sure. Please send us your contact information and address. We will send you the appropriate samples in time.

*

Chapter 1.

Conclusion

Coffee needs long-term storage and long-distance transportation. In order to retain the aroma and quality of coffee, of course, it is inseparable from the high barrier of packaging bags. Among the materials currently used, aluminum and aluminized film have the best barrier. The best material structure is: PET / VMPET / PE, PET / Al / PE.

Tell us your requirements. We can provide to you with reference opinions free of charge, so that you can get the most favorable price and reliable product quality.

LIBO Packaging

√Professional team both in production and R&D .

√ The excellent high quality Standing zipper plastic bag food packaging bag supplier in the world.

√ The largest high quality non-adhesive tape supplier in the world.

√ Sound capital foundation, international advanced management system.

√ Professional packaging supplier and quick response, delivery on time.

√ Innovative ,Pragmatic, Collaborative development conducting philosophy, Built solid base for LIBO of leaping future.

Professional production: Auto-packaging Plastic film ,Compound packing bag, Plastic roll film, Kraft paper Pouch,Vacuum bag, Aluminum foil bag, Spout pouch and Shape bag etc.

If you are interesting our company new products catalog also .Please help to contact with us soon !!!

(24*7 After Sales Services) Then We will offer more competitive products price for you in time .

Transparent vacuum bag for food

Transparent vacuum bag for food , Transparent food vacuum bag may be the most common and widely used vacuum bag in the market. Material: PET / PE or PA (NY) / PE. The material is highly transparent and can clearly see the storage of the product. In addition, the material also has high barrier, waterproof and moisture-proof, which can keep the food dry to the greatest extent and prolong the storage period of the food.

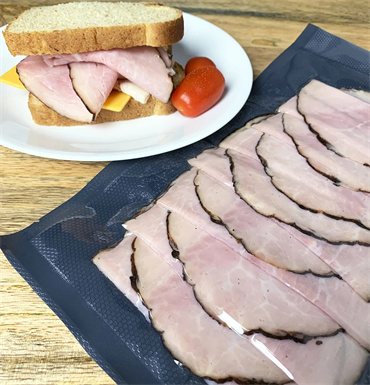

Transparent vacuum bag for meat food

Transparent vacuum bag for meat food , Special attention should be paid to two points: 1. Meat food contains fats, and the material PE is required to have fats-resistance to ensure that the packaging bag is heat sealed firmly. 2. Some meat foods (such as bones, chicken wings, etc.) have sharp edges and corners, which are easy to puncture the packaging bag when vacuumizing. It is necessary to consider whether the anti puncture ability of the material can ensure the safety of the packaging bag. Ideal material structure: PA (NY) / PE, in which PE needs to have high tensile strength. LIBOPACK can produce such PE materials specially used for meat food packaging.

Embossed vacuum bag

Embossed vacuum bag has two advantages: 1. Embossing can prevent food from sliding. During vacuuming, the contents will slide slightly with the air flow direction, affecting the working efficiency. The friction coefficient after embossing will increase, and the contents are not easy to slide. 2. Embossing helps to discharge the air from the packaging bag, because a certain gap is formed between the uneven embossing and the contents, and the air will be easily discharged from these spaces.

Transparent vacuum bag for meat food

Transparent vacuum bag for meat food , This is a vacuum bag made by a special process. It is divided into bottom film and lid film. The lid film is a transparent material, relatively thin, PA (NY) / PE, with a thickness of 50 microns. It will shrink and tightly wrap the contents during vacuumizing. The bottom film is an opaque three-layer material (PET / PA / PE), with a thickness of more than 120 microns. It is not easy to deform and shrink during vacuuming. The flat panel can customize the company’s brand and product information.

Recyclable vacuum bag

This kind of vacuum bag is relatively common. Transparent and high barrier materials can display the storage information of the packaging. At the same time, they can effectively prevent moisture, mildew and pollution, and can also be stored at low temperature. In order to save cost, take the stickers on the packaging bag to indicate the weight, nutritional composition, bar code and other information of the product.

Recyclable vacuum freezing bag

The use of vacuum bags to pack meat products often requires frozen storage and transportation, which requires that the packaging materials have the properties of moisture-proof, water-proof and block air, so as to ensure the freshness of food. At the same time, the materials also need to be resistant to low temperature, abrasion-resistance, so as to ensure that the packaging bags do not break and keep the food intact during long-distance transportation.

Food grade materials and BPA free.

Embossed vacuum roll film

Embossed vacuum roll film has two advantages: 1. Anti- skidding. The special production process increases the friction coefficient of the material surface, prevents the contents from sliding and easy to use; 2. The surface of the material is embossed, which is conducive to the discharge of air and the preservation of the contents.

This kind of roll film is mainly used in families. According to the size and quantity of packaging, it can be cut into the required size by vacuum sealing machine, so that food can be easily saved, which is convenient and economical.

Custom size embossed vacuum roll film

Custom size embossed vacuum roll film , Household vacuum sealing machine have different sizes. LIBOPACK can customize and produce vacuum bag roll films of different sizes according to your requirements. At the same time, can also customize the length of roll films. The commonly used specifications in families are 5m / roll and 10m / roll.

These transparent materials can be recycled. In order to protect the earth’s resources, please consciously classify and recycle the garbage.

BPA free embossed vacuum roll film

Whether for household use or industrial production, you can customize embossed vacuum roll films of different thicknesses and sizes in LIBOPACK. We solemnly promise that the materials used are food grade and do not contain BPA, non-ketene ,non-benzene ink , non-smell ,easy to be sealed by heat , good shrinkage.

Black embossed vacuum bag for meat food

Black embossed vacuum bag for meat food , High barrier materials can effectively block the entry of external water vapor and air, and prevent food from being polluted at the same time; After vacuumizing, the inside of the packaging bag is in a highly anoxic state, which can inhibit the reproduction of bacteria and other microorganisms and prolong the storage period of food.

However, this kind of high barrier vacuum bag is not suitable for packaging fresh fruits and vegetables. Because there is no oxygen in the packaging bag, fruits and vegetables cannot breathe normally, which will cause physiological diseases.

Black embossed vacuum bag for meat food

Among all the materials for packaging meat products, PA (NY) is the best choice, because it not only has high barrier performance, but also has high transparency, good flexibility, oil resistance and high temperature resistance. Its physical properties will not change even in low temperature environment.

The bottom material is embossed, anti-skidding and easy to air-out. Black is made by adding black master-batch in the production of PE material, non-toxic, non-smell and BPA free .

Three sided seal retort pouches for frozen pet food

Recyclable embossed vacuum bag for food

The front material is transparent PA (NY). The highly transparent effect allows consumers to confirm the preservation of food in advance; The back material PA (NY) / PE. After embossing, the black PE material has good anti-skidding and air-out effects. At the same time, black can effectively block the light and prolong the shelf life of food.

The materials used are food grade materials without BPA, which are convenient for recycling.

Transparent embossed vacuum frozen bag

The use of vacuum bag packaging meat products, often need to be frozen storage, packaging materials are required to withstand low temperature, good barrier, so as to reduce frozen food surface drying and hardening, loss of moisture and grease, taste is not good, so PA (NY) /PE, can be perfect to solve this problem. The material on the back after embossing, thickness also increased, It is still relatively flat after vacuumizing, easy to stacking storage .

Aluminized film embossed vacuum bag

Aluminized film embossed vacuum bag , It is popular for its excellent barrier. The back is aluminized film, which can not only block the invasion of air、water vapor and pollutants, but also block light and temperature. The front is made of highly transparent materials, which can clearly see the preservation of the packaging.

LIBOPACK stores various sizes of aluminized film vacuum bags for a long time. You are welcome to call or send E-mail to order, with quality assurance and preferential price.

Aluminum foil vacuum bag

Aluminum foil vacuum bag , Its barrier performance is the best. Material structure: PET / Al / PA / LLDPE or PET / Al / PA / RCPP. It is very suitable for packaging meat products. It can prevent moisture, mildew, pollution and oxidation. It can also withstand high-temperature retort to sterilization at 121-135 ℃, and prolong the shelf life of food. There is no need to worry about the deterioration of food during long-distance transportation and long-term storage.

Of course, you can customize product information, food grade materials and BPA free.

Black embossed vacuum bag for meat food

The use of vacuum bags to package meat products requires that the materials have high barrier properties to block the external water vapor and air. At the same time, it is also necessary to lock the water in the meat products. Otherwise, the meat products will accelerate the volatilization of water and become dry and hard in the frozen state, losing its original taste.

The sealing strength of the packaging bag is firm, safe and reliable, which can ensure the integrity of food and facilitate long-distance transportation and storage.

Retort vacuum food bag

Packaging meat products with vacuum bags often needs high-temperature retort to sterilization, so as to maximize the shelf life of food and maintain the original fresh taste of food. Of course, frozen storage is also essential. Based on this, we choose PA (NY) / PE, a food grade material with high barrier, which can withstand 121-135 ℃ high temperature retort for 30 minutes, and then refrigerate at 0-4℃ low temperature.

Retort vacuum pet food bag

Meat products for pets need to be packaged with high barrier materials to prevent the entry of moisture and air. After vacuumizing, they are retort to sterilized at high temperature for 30 minutes, and then stored at a low temperature of 0-4. Only in this way can we ensure that the food does not deteriorate, be polluted and oxidized, and maintain the original flavor and taste within the shelf life.