| MOQ | 50K-80K Pcs |

|---|---|

| Size | 50*70mm(Min) 350*600mm(Max) |

| Material | BOPP/PET+PET/PETAL/Kraft Paper/+LLDPE/CPP |

| Thickness | 50Mircons-120Mircons (2Mil-5Mil) |

| Function | Punch Hole, Handle, Metallized |

| Printing | D-Met Printing, Vanishing, Matte Finishing, Stamping |

| Products | Normal Material Use |

| Chips | BOPP/CPPAL,BOPP/PETAL/CPP |

| Noodles | BOPP/PE,PET/PE,BOPP/CPP |

| Candy | BOPP/CPP,PET/PE |

| Frozen Foods | BOPP/PE,BOPP/CPP |

| Industry | Products Use |

| Dry food | Snack bars, Nuts, Cookies, Biscuits, Macaron, Sandwich cake |

| Inflatable food | Potato chips, Potato crisps, Snack chips, Fried chips, Fried chicken bar |

| Confectionery | Jawbreaker, Gummy, Hard Candy, Lollipop, Chocolate bar, Gum, Rainbow Candy, Sandwich candy, Fruit powder sugar |

| Others | Noodles, Frozen dumplings, Pizza, Spices, Seafood |

Flat Bottom Bags

Flat bottom bags is also called block bottom pouch,Quad seal pouch or Box pouch.

Advantages of flat bottom bags:

1.The side gussets of the bag can be expanded to provide enough space.

2.When flat bottom bags is full of products and set on the shelf, the obvious and unique appearance can attract the attention of buyers in the first time, which is your best choice for product promotion and branding.

3. The flat bottom bags produced by LIBO company are made of high-strength materials and laminated by special technology to improve the sealing of the packaging bag, resist oxygen, moisture and UV light, and perfectly extended the shelf life of the product.

4. The front, back, sides and bottom of flat bottom bags can be printed, providing a flexible choice for designs layout, text description and brand promotion.

5. The flat bottom bags can be added with zipper、valve and hang holes . flat bottom bags is mainly used in high-end product packaging, such as coffee, pet food, nuts (dried fruit), milk powder and so on. LIBO’s high-quality flat bottom bags focusing on improving the product quality.

We are committed to be your loyal partner in your business.

Flat Bottom Bags Specifications:

Name: Flat Bottom Bags/block bottom pouch/Quad seal pouch /Box pouch Quad seal pouch / Box pouch.

Size: According customers designs

Material: PET/AL/LLDPE

Thickness:60– 125micron

Flat Bottom Bags— The stand up pouch provides consumers with market-friendly features like zipper reclosure, Tear notches. The versatility of hand hole features .Strong shelf presence . Feature :With excellent sterilization feasibility.Low temperature Storage availability and barrier property.

Different kind of styles pouch for choice :Stand up pouch with zipper /Quad seal Pouch with value /Middle seal Pouch/Auto-Packaging plastic roll film/Kraft paper aluminum foil pouch etc .

1、what is the Flat Bottom bag ?

Flat bottom bag is also called 8 edge sealing flat bottom bag ,The eight sides of the bag are sealed.

The bottom of the bag is flat.

Flat bottom bag is the best in all of the packaging bags of the flexible packaging industry.

2、All names of the Flat bottom bag ?

Flat bottom bag is also called block bottom pouch ,quad seal bag(pouch) or box pouch.

3.Application of the Flat bottom bag ?

The packaging bag is mainly used in the packaging of high-grade food, nuts, coffee, tea and pet food. Because this kind of stand bag has distinctive visual appearance and high-end atmosphere, it can attraction customers’ strong desire to buy at the first time. At the same time, this kind of packaging bag can be seted with transparent window, zipper, one-way degassing valves and hang hole, which increases the many functions of the packing bag.

4.What are the types of the Flat bottom bag ?

Depending on the different products you want to package, you can choose different functional Flat bottom bags:

Zipper flat bottom bags

Foiled flat bottom bags

Aluminum flat bottom bags

Clear flat bottom bags

Flat bottom bags with tin tie

Zipper flat bottom bag :Because of the zipper, the packaging bags can be closed in time to keep the contents fresh.

Fioled flat bottom bags :The remarkable feature is high barrier properties, suitable for packaging coffee, tea, nuts, pet food and so on.

Clear flat bottom bags:This kind of stand up bag is inferior to foiled flat bottom bags, but this kind of packing bag is cheap and recyclable. In addition, the special design allows customers to preview the products inside before buying, which stimulates their desire to buy.

Aluminum flat bottom bag:due to used the best barrier metal aluminum, so the maximum against oxygen, moisture and uv lights, extended the product shelf life. suitable for packaging coffee, tea, pet food.

5.What are the benefits to using flat bottom bag for packgaing ?

Compared with other types of packaging bags, flat bottom bags have the following advantages: unique packaging shape, strong attraction, and maximize the image and influence of the product.

The unique structure design of the packaging bag increases the storage space. In this sense, the cost of flat bottom bag is relatively friendly.The bottom of flat bottom bag is flat, which makes it easier to set on the shelves. Due to it’s unique shape, it is often placed in the most obvious place on the shelves of shopping malls.

LIBO company has a professional design team to design perfect flat bottom bags for your products.

6.What are the materials used for making a flat bottom bag ?

PA(NY) 、BOPP 、PET、Kraft paper: The surface materials are used for printing ;

VMPET 、AL(Aluminum foils) : middle materials, with barrier effect.

CPP 、VMCPP、PE : bottom material, with heat sealing effect.

7.What types of printing is used on a flat bottom bag ?

At Libopack , all packaging bags can be produced with Gravure printing or Digital printing.

8.What is the metalized flat bottom bags & pouches ?

Metalized flat bottom bags &pouches are used mostly for storing products that are very light sensitive . The most obvious feature of this material is that the middle layer uses metal foil, which has excellent barrier properties.

In addition, metalized flat bottom bags & pouches have metallic gloss, and the display effect on the shelf is very good.

9.How do you test to the quality of a flat bottom bags & pouches ?

Friction Testing

The friction coefficient of raw materials directly affects the following processes:

Production speed and output of printing and bag making

Production speed and output of automatic packaging machine

Tensile testing

The tensile strength of the material directly affects the structural strength of the packaging bag.

Heal seal testing

Use professional instruments for random check to the packaging bags.

Whether the tightness of the packaging bag is up to standard or not depends on the lamination strength of the joint between the two ends of the zipper and the two sides of the packaging bag. To solve this problem, Professional technical personnel and equipment are the key. Libopack company has 20 + years of experience in the flexible packaging industry and is confident to do it.

10.What is the minimum order quantity of the flat bottom bags & pouches?

For Libopack , it all depends on the customer’s order.

If you are a startups , I am willing to grow up with you and support each other. We will choose the right plan for you and fully support your business.

If your business is in high-speed development, we will fully cooperate with your needs, guarantee the good quality and quantity to complete your order.

11.How many colors can be printing on a flat bottom bag & pouch ?

At Libopack, the gravure machine can printing 10 colors, and the digital machine can printing 10 + colors.

If your design has special requirements, welcome to inquire.

12.What conditions determine the cost of flat bottom bags?

The size, thickness, material and printing colors of the packaging bag (example: the colors is more,the cost will be higher)

Quantity of order (if your order can’t reach the minimum order quantity, don’t worry, we will choose digital printing to save the cost of copper plate and shorten the delivery time)

Packaged products (if the packaged products are different, the materials used are also different. For example: for packaging coffee, in order to against UV lights and indoor light, aluminum foil must be used. The cost is higher .If it is candy or food, you can choose ordinary transparent materials, the cost will be lower. )

In the society of commodity economy, a large number of various commodities are produced. In the process of commodity circulation, a large number of different kinds of packaging are used. For example, transportation packaging, sales packaging and so on. In this sense, without packaging, there will be no goods.

The rational use of packaging not only creates huge profits for producers, but also brings more benefits to consumers.

For example, rice is packed with high barrier plastic film, and the shelf life is increased from about one month in bulk packed to more than one year.

With high barrier properties materials made into exquisite packaging bags, coffee— the delicious drink, can travel across the ocean to China, allowing Chinese consumers to taste delicious drinks other than tea.

Chapter 1. Comparison between flat bottom bags and stand up bags 、gusset bags.

1.1 Flat bottom bags has 8 edges are sealed, so it is also called 8 edges sealing flat bottom packaging bag, stand up bag has only 4 edges sealed, and gusset bag has only 5-6 edges sealed.

1.2 The bottom of the flat bottom bag is flat, while the bottom of the stand up bag and the gusset bag are bulges after they are filled with products, which leads to different standing effects on the shelf.

1.3 Flat bottom bag has 5 sides that can be printing , stand up bag has only 2 sides can be printing ,gusset bag has 4 sides can be printing.

1.4 The cost of the machine for producing flat bottom bag is twice that of the machine for producing stand up bag and gusset bag, and the level of specialization and automation is much higher. In addition, the output of flat bottom bag will be less in the same time, so the comprehensive cost of flat bottom bag will be higher. However, considering the large internal space of this kind of packaging bag and the good shelf display effect, certainlyFlat bottom bag has obvious cost-effectiveness.

1.5 Of course, these three kinds of bags can be specially customized. Zippers and one-way degassing valves、tin tie can be added according to customers’ requirements.

Chapter 2.Application of the flat bottom bag & pouch

Flat bottom bag has a wide range of applications, because it has superior performance to compared with other packaging bags, below are some of the products packaged using these bags:

Coffee/Tea/Cereals/Pet food/Snacks and nuts etc.

Chapter 3 Top 8 benefits of the flat bottom bag ?

3.1 Flat bottom bag can be standing stable, conducive to shelf display, deeply attracted the attention of customers.

3.2 Flat bottom bag has five printing layouts, which provides more space for pattern design and text arrangement.

3.3 Because the bottom of the quad seal pouch is flat, if the packaging bag is placed flat, the bottom can also be used as a perfect display platform.

3.4 Flat bottom bag stands firmly, which is conducive to the perfect display of brand information to customers.

3.5 Flexible packaging materials have a variety of functions, such as thickness, barrier properties and metallic luster. In addition, printing 10 + colors, they will help to the design and promotion of brand image. These advantages can not be compared with cartons, glassware, metal boxes and wooden boxes.

3.6 Flat bottom bags can also be added with zippers. Other materials (such as cartons) can not achieve this effect.

3.7 Flat bottom bag has a unique looks, which can be easily recognized by consumers and is conducive to the establishment and protection of the brand.

3.8 Flat bottom bag has five sides, which can be printed in a variety of colors. The product has a outward appearance is fine and promotional is very good .

Chapter 4 Add-ons (Features)

The use of flat bottom bag is depending on the product and your needs. The following add-ons are available.

4.1 Tin Tie application

As noted above, these packaging bags are depending on the needs of customers. The functions of the Tin Tie are similar to zippers. After the bags are opened, they can be resealable. In addition, they also have the following advantages:

4.1.1 After each used, you can use tin tie to roll up the packaging bag from top to bottom, so that you can clearly know how many products are still in the package.

4.1.2 After each used, the products in the packaging bag will also be reduced. At this time, you use Tin Tie to roll up the packaging bag from top to bottom, and the space of the packaging bag will also be reduced, saving the storage space. It is the best choice for your business trip and travel.

4.2 Hang Holes

Ergonomic handle

Euro pouch hole

4.3 Valve Application

Such are perfect add-ons valves that will never let you down , they will allow de-gassing to take place until inner -outer pressure equilibrium is attained and lastly bars off moisture and oxygen.

4.4 Front Tap Zipper

Ordinary zipper packaging bag, when used for the first time, must tear the top of the packaging bag, so it is very cruel to destroy the perfect image of the packaging bag, consumers are not willing to use it to store other products, resulting in a waste of resources.

The front tap zipper completely overcomes the above shortcomings, perfectly retains the overall appearance of the packaging bag, and can be reused, which is environmentally friendly.

Chapter 5 Common flat bottom bag in the market

LIBOPACK has a variety of packaging bags for you to choose from. These packaging bags are mainly distinguished by the type and function of the materials used. The following are what we offer :

5.1 Kraft flat bottom bag & pouch with window

If you package goods that are not refrigerated for retail, you can choose the kraft flat bottom bag

As kraft paper has the texture of natural materials, the printing effect is friendly, natural, simple and elegant, which is a unique design style.

However, due to the difference between kraft paper and plastic, the colors should not exceed 5 in design. The design should be simple and the words should not be too many.

5.2 Transparent flat bottom bag with zipper

This kind of packaging bag selects 2-3 layers of transparent material, with less printing area and transparent part left for convenient display to consumers.

This type of packaging bag has the advantages of simple material, less printing area , of course, the cost is lowest.

5.3 Metalized Quad seal bags & pouches

The packaging bag uses metallized material, which has two functions.

5.3.1 improve the barrier.

5.3.2 increase the metallic luster of patterns and words, especially in the light, the effect of the whole packaging bag is easy to attract the attention of consumers.

5.4 Foil flat bottom bags & pouche

The packaging bags is usually made of 3-4 layers of materials, which have very strong barrier properties and protection from high temperatures 、UV light 、oxygen and moisture. In addition, the packaging bags can also be printing. If you needs, please don’t hesitate, LIBOPACK’s professional and technical team will not let you down.

5.5 Flat bottom bags with Front tap ziplock

The main purpose of using this kind of ziplock on the packaging bag is to prevent children from opening it easily, because when the zipper of the packaging bag is tear open, the hidden ziplolck will not be easily found by children.

Chapter 6 Material choice

The material structure of flat bottom bags is usually made of 3-4 layers of material, which completely depends on the function of the packaging bag. We’ll take the 3 layers packaging bag as an example:

Inner film : LLDPE or CPP 、RCPP

Barrier film : VMPET or AL 、 NY、 PVDC、 EVON

Out layer : Mattpet 、Mattoppp 、Bopp 、 pet 、 Kraft

These three materials have different functions:

Out layer: the main function is to printing color, and at the same time, it must have the performance of high temperature resistance, so as to ensure that the packaging bag is not damaged in the high temperature lamination process, the packaging bag is flat, and the structure is firm.

For example, PET can withstand high temperature of 150 ℃ and low temperature of minus 70 ℃, far exceeding that of BOPP and Mattopp. After high temperature lamination, the packaging bag has a flat appearance and no wrinkle, which can’t be compared with other materials.

At the same time, the oxygen and moisture permeability of PET are also very ideal to ensure that the product does not go bad and extend the shelf life.

Barrier film: the main function of the materials used is to improve the high barrier properties of the packaging bag, ensure that the contents are not affected by oxygen, moisture and UV lights, and extend to shelf life of the product.

Among them, Al (aluminum) is the most perfect barrier. Of course, the cost is also higher. In order to save the cost, you can choose VMPET or VMCPP.

In LIBOPACK, our product design team will design suitable packaging bags according to your needs and cost-effectiveness. You only need to tell us the following details, and the rest of the work will be left to us:

What is the product you want to package?

What is the shelf life of the product?

What are the storage conditions of the product?

What is the effect of the appearance design of the packaging bag?

LIBOPACK will fully cooperate with your request, please trust us.

Chapter 7 Flat bottom bags & pouches FAQs

9.1 The delivery time of flat bottom bags.

If you are the first one to customize flat bottom bags in LIBOPACK, we will make copperplate with a delivery time of 15-25 days. If it’s a repeat order, it will be ok within 15 days depending on your bags order quantity.

9.2 If we order flat bottom bags & pouches, what is the minimum quantity?

Generally, the minimum quantity per order is 30000-50000 bags. in special cases, if you are a start-up company or your customized packaging bag is to understand the market acceptance of new products, we can consider to use the “Digital printing” for you. The minimum order quantity is 200 bags. For this, please pay attention to the “Digital printing” column of LIBOPACK website.

9.3 Can LIBOPACK provide free samples ?

Sure. Please give me the detailed address. In order to ensure that the sample is closer to your product needs, please tell me the details: product weight, storage and transportation conditions, shelf life, etc.

9.4 How many colors can you print ?

Gravure printing machine can print 10 colors and Digital printing can be 10+ colors. If you have special requirements, please contact our sales service specialist to reflect your ideas to the design team in time.

9.5 Dose your factory hold any Bag stock ?

Most of the products are custom-made and manufactured to order. In addition, there are some unprinted flat bottom bags, the size of which is often used in the market.

9.6 How can I confirm you have received order ?

The first time we receive your order, our sales staff will confirm with you and arrangement the next work in time.

9.7 Is your product safe for food packaging? Are there any relevant certificates and test reports?

Our company has passed ISO9001 certification. All raw materials (including ink and glue) have relevant certification and test reports. Please feel free to use them. If you have special requirements, we can also provide SGS and FDA test reports for your packaging.

9.8 Can your products be recycled?

Sure , all our products are FDA approved and eco – friendly .

9.9 How to confirm the quality of the product before delivery?

First of all, both parties have confirmed all the packaging details and quality requirements of your order before production.

Secondly, according to the special requirements of packaging bags, we will analyze which link in the production process is easy to have problems, and take good control measures to remedy in time.

Finally, we will carry out sampling inspection on the packaging bags, and all unqualified products will be scrapped.

Do the above three steps, basically ensure that the qualified rate of products meet your requirements. Of course, if you are still skeptical, you can appoint a third party to conduct sampling inspection. We welcome your client to follow up the production progress in my workshop.

If the abnormal situation still appears after the use of the packaging bag, please rest assured that we will not evade the responsibility and will deal it together with you.

Step 1: please send us a video or picture.

Step 2: please describe all the details of the exception in words.

Step 3, after analysis, if we confirm that it is our responsibility, we will make compensation and exchange the goods in time.

10. LIBOPACK’s Flat bottom bags

At LIBOPACK ,We are a responsible supplier.

We have 20 + years of industry experience, experienced countless difficulties, step by step to today, there are successes, failures, gains and losses. Our services aim— beautify your life with our packaging.

At LIBOPACK , We are a team with professional technology

Advanced production equipment, professional technical personnel and customer first service concept, let you rest assured that the products to us.

At LIBOPACK, reducing cost is our aspire.

Our price may not be the lowest, but it must be lower. Give us your packing bag and then we will give you a surprise price.

We will not promise to you at will, but as long as we have promised, we will do it well.

Conclusion

Since the 1980s, packaging has become an indispensable part of people’s life. Many countries began to add management to the packaging industry. More and more designers began to realize the importance of packaging design to environmental protection. People began to put forward the topic of recycling.

Nowadays, packaging design pays more attention to the performance of corporate image, and brand image is further emphasized in packaging. At the same time, under the influence of environmental protection, the concept of packaging is “natural, primitive and healthy” as the mainstream, and the external image of packaging is welcomed by the society with “lightweight and small volume”.

Here, we have discussed flat bottom bags, from materials to processing, from the shape of packaging bags to various details. We have described them in detail one by one. I believe you also know about LIBOPACK. Let’s determine what you are most concerned about? That’s the cost, right?

We always firmly believe that we have the advantage of cost, because

- Purchasing cost advantage of raw materials

- The advantages of processing equipment let us reduce wastageand lower production costs.

- Fine management level ensures the qualified rate of products.

Of course, if you still don’t believe it, you might as well have a try. Welcome to call or send e-mail, let’s discuss a topic –— price、 price and price.

LIBO Packaging

√Professional team both in production and R&D .

√ The excellent high quality Standing zipper plastic bag food packaging bag supplier in the world.

√ The largest high quality non-adhesive tape supplier in the world.

√ Sound capital foundation, international advanced management system.

√ Professional packaging supplier and quick response, delivery on time.

√ Innovative ,Pragmatic, Collaborative development conducting philosophy, Built solid base for LIBO of leaping future.

Professional production: Auto-packaging Plastic film ,Compound packing bag, Plastic roll film, Kraft paper Pouch,Vacuum bag, Aluminum foil bag, Spout pouch and Shape bag etc.

If you are interesting our company new products catalog also .Please help to contact with us soon !!!

(24*7 After Sales Services) Then We will offer more competitive products price for you in time .

Customized Block bottom pouch with windows

The only purpose of designing transparent window is let customers preview the content before buying, and arouse customers’ desire to buy. At the same time, these stand up bags have unique appearance design, which can attract buyers’ attention. In addition, these stand up bags are all made of high barrier materials, which improves the shelf life of the products

Metalized Quad Seal Bags or Pouches

Metalized Quad Seal Bags or Pouches are used for various applications. But, the nature of their application determines the types and number of films to get laminated to provide barrier properties against oxygen, moisture, UV lights, odor, and other contaminants. These are stand up pouches suitable for dry goods packaging, frozen free products, edible products, and liquid products. For convenience reasons, several accessories can also get fitted alongside quality custom printing.

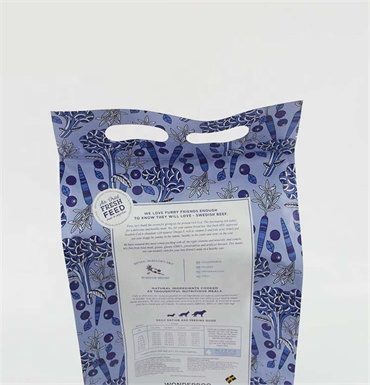

Block bottom pouch for pet food

Matte materials are mostly used in packaging bags. Their colour and lustre is natural, kind and attractive. The bottom of the bags is flat and can stand up gracefully on the shelf. In addition, the block bottom pouch are made of three layers of materials, which improves the barrier properties and can preserve the fresh taste of the contents for a long time.

500g Quad seal bags for food

Quad seal bags are made of high barrier materials and laminated by special process, which can against Oxygen, Moisture and UV lights, ensure the freshness of contents and prolong the shelf life of food, They come with a flat bottom that allows them to stand upright on the shelf. In addition,They also fixed a re-close able zippers that can be opened repeatedly, so that it can be closed in time after opening.

Matte Flat Bottom coffee Bags with valve

Mostly the flat bottom bags with valve are used for packaging roasted coffee ,when coffee beans are roasted ,they tend to release carbon dioxide gas continually for 7+days .In that case, one-way degassing valves are fitted on coffee packaging bags to allow the gas to get expelled. Accumulate of excess carbon gas can lead to pouch bursting, In addition, the surface material of the coffee bag is Matt PET or Matt OPP, which has special visual effects and can attract customers’ attention at the first time, making your products stand out in many stand up pouches in the market.

Black Quad seal flat bottom coffee bag

Black quad seal flat bottom bag is famous in coffee packaging. Many love these pouch due to their excellent barrier properties. Although aluminum foil is the primary material, other materials such as LLDPE and PET are used to keep off oxygen, moisture, UV lights, odor, and other external hazardous effects. Lastly, these bags are FDA approved BPA free and customized using hang holes, tear notches, zippers, round corners, branding, and transparent windows to fit your packaging needs.

Clear Quad Seal Bag & Pouch

Clear quad seal bags are mostly used for packaging edible products, such as coffee, tea, cereal, some snacks, nuts, etc. Because consumers can check the preservation of the food in the bag through the clear window before buying. This is the most effective way to motivate customers to buy. Of course, the material of this kind of packaging bag is food grade, and the barrier performance of the packaging bag is improved through the lamination process, which can ensure that the food can reach the expected shelf life.

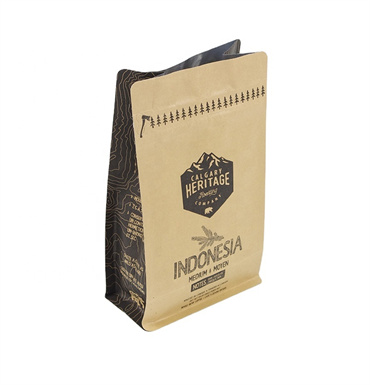

Brown kraft flat bottom bags with zipper

Because kraft paper is used as the surface material, the printed pattern and color are very simple, which makes the appearance of the whole packaging bag look very natural, simple and elegant. At the same time, we don’t have to worry about the barrier performance of this design. We use high barrier materials for processing. In addition, we fixed the resealable ziplock

White kraft paper flat bottom bag with tin tie

The flat bottom bag with tin tie is mainly designed for food packaging, tea packaging and coffee packaging. A tin tie is fixed on the top of the packaging bag, which is convenient to fold from the top to the bottom of the packaging bag and sealed with the tin tie. With the reduction of the content, the volume of the packaging bag is also reduced and does not take up more space. It is the best choice for your business trip and travel

Matte quad seal bag with valve

The roasted coffee beans will continue to release carbon dioxide gas, so the valve on the packaging bag should ensure that the gas is discharged in time, and keep the natural sweet smell of the coffee beans in it. The surface material of the packaging bag shows a matte effect and make a deeply impression on consumers. Of course, you can also customize the printing. There are 5 panels to design your printing content.

Matte Flat bottom bag & pouch for food

The flat bottom bag in the picture is used to packed the ordinary salt, so the added value of the product is not high. Therefore, ordinary and transparent materials should be used as much as possible. The two-layer structure and lamination can ensure the barrier properties and protect the salt from moisture deterioration. In addition, the surface material has a matte effect, which makes it feel different from the rest of other packaging bags .

White kraft paper flat bottom bag with tin tie

In most cases, the structure of the coffee bag is made of 3-4 layers of material after lamination, and the middle layer material will be AL, in order to improve the barrier properties of the packaging bag. It should be noted that the sealing performance depends on whether the joint between the two ends of the zipper and the two edges of the packaging bag is strong. It all depends on the professional level of machinery and workers.

Black Quad seal bag for food

Black is always the designer’s favorite classic color. However, if there is no transparent part in the packaging bag, consumers will not be able to watching the products inside. We want to thank the designer for his originality. The side gusset plate of the packaging bag leaves us a small window, which is very humanized. Don’t worry. At LIBOPACK, we used food grade materials.

Flat bottom bag & box pouch for tea

There are two important indicators of whether flat bottom bags are qualified or not

1. Whether the flat bottom bag surface is smooth or not, otherwise it will affect the appearance of the packaging bag, of course, it will also affect the sales and brand promotion.

2. Whether the lamination of the material is firm, otherwise the contents will be affected by moisture, especially the packaging of coffee and tea.,These products should be kept dry.

250g Flat bottom bag for tea

In the field of packaging, flat bottom bag is mostly used to package tea, because high-end products need exquisite packaging. Usually, In LIBOPACK company, we choose Kraft / Al / PE. Due to the use of Al, the barrier of the packaging bag is greatly improved to ensure the fragrance and freshness of tea.

250g Foil Quad seal flat bottom bag coffee bag

The 250g quad seal flat bottom coffee bags are famous in coffee packaging. Many clients love these pouch bags because of their unique barrier features. The bag is designed with a flat bottom that allows it to stand upright on any shelves. High-quality materials like PET, PE, VMPET, and LLDPE are used to protect the packaged content from moisture, oxygen, UV lights, and other external hazardous effects. Lastly, our bags are FDA certified, eco-friendly, and BPA free.

500g Matte Flat bottom quad seal bag with window

Our matte flat bottom quad seal bags are found in custom sizes. The matte finish is a great style that makes them look good, although dull. Mostly, these bags are used for packaging edible foods, and that is why they are FDA approved and made of laminated films for high barrier reasons.If you need custom printing, we have rotogravure and digital printing options for you. Lastly, these self-standing bags are manufactured in up to 12 matte colors, and with various accessories such as round corners, tear notch, hang holes, degassing valves, handles, zippers, and many others.

Brown kraft paper Quad seal bag& pouch with valve

Kraft paper is a natural material, the printing effect is particularly friendly and natural, so that the whole packaging bag has exudes charming charm, coffee comes from nature, the overall effect of the packaging bag should also have a kind of temptation to return to nature. In the material design, we added Al (aluminum) to improve the barrier performance. Ensure the pure natural aroma of coffee, please rest assured to use.