| MOQ | 350KG–1000KG |

|---|---|

| Size | 50*70mm(Min) 350*600mm(Max) |

| Material | BOPP/PET+PET/PETAL/Kraft Paper/+LLDPE/CPP |

| Thickness | 50Mircons-120Mircons (2Mil-5Mil) |

| Function | Punch Hole, Handle, Metallized |

| Printing | D-Met Printing, Vanishing, Matte Finishing, Stamping |

| Products | Normal Material Use |

| Chips | BOPP/CPPAL,BOPP/PETAL/CPP |

| Noodles | BOPP/PE,PET/PE,BOPP/CPP |

| Candy | BOPP/CPP,PET/PE |

| Frozen Foods | BOPP/PE,BOPP/CPP |

| Industry | Products Use |

| Dry food | Snack bars, Nuts, Cookies, Biscuits, Macaron, Sandwich cake |

| Inflatable food | Potato chips, Potato crisps, Snack chips, Fried chips, Fried chicken bar |

| Confectionery | Jawbreaker, Gummy, Hard Candy, Lollipop, Chocolate bar, Gum, Rainbow Candy, Sandwich candy, Fruit powder sugar |

| Others | Noodles, Frozen dumplings, Pizza, Spices, Seafood |

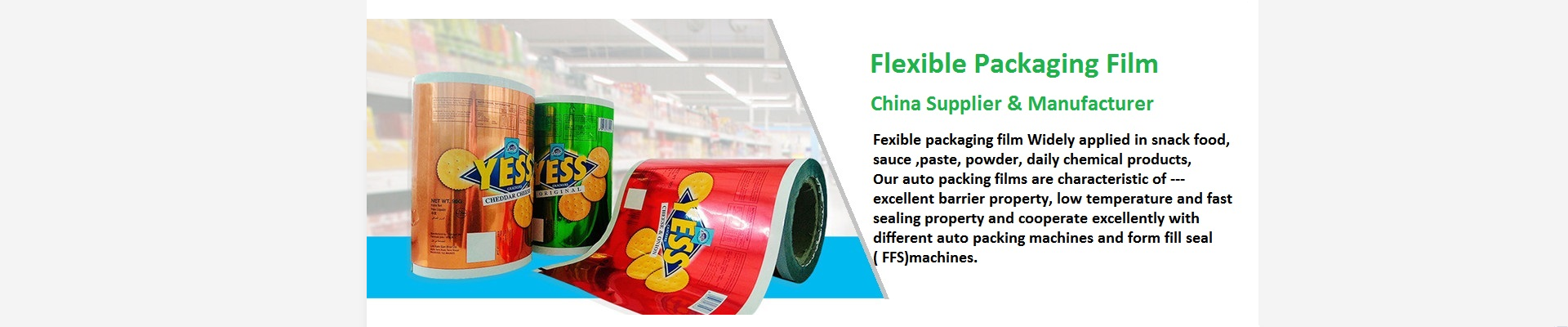

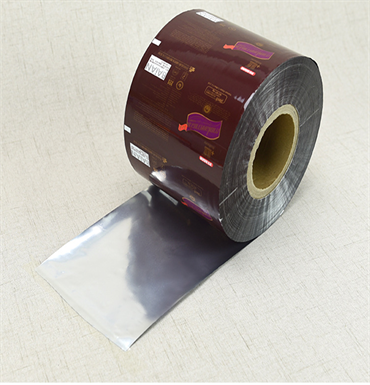

Flexible packaging film

Flexible packaging film is applied to automatic packaging machine. Its main function is to save labor cost and improve production efficiency. It is used for food or non food packaging.

Most flexible packaging films are made of two layers of materials. In addition, there are three or four layers of materials to meet the needs of special functions of products. However, their thickness is usually less than 100 microns, which is determined by the heat sealing effect and packaging speed of automatic packaging machine.

At LIBOPACK:

Gravure printing : printing up to 10 colors ;

Digital printing : printing up to 24 colors.

MOQ : Gravure printing start 300KG. Digital printing start 200 pcs.

Delivery time : Gravure printing: 10-12 days. Digital printing: 5-7 days.

Different kind of styles pouch for choice :Stand up pouch with zipper /Quad seal Pouch with value /Middle seal Pouch/Auto-Packaging plastic roll film/Kraft paper aluminum foil pouch etc .

Flexible packaging film —- Frequently asked questions you are most concerned about :

1、What is flexible packaging roll film?

Flexible packaging roll film is a product made of various materials (plastic or paper), first printed (or not printed), and then laminated with other materials.

2、 Classification of flexible packaging film:

2.1. classification by material:

plastic roll film : after different plastics are printed or not printed, then are laminated ;

Paper /plastic roll film : kraft paper / plastic , Rice paper / plastic; Paper / glue;

Paper / PLA (biodegradable and recyclable) .

2.2. By function:

Transparent roll film (printed or not): common are OPP / CPP, PET / PE, etc.

High barrier roll film: aluminum foil or aluminized film will often be used. Common are: PET / VMCPP, BOPP / VMPET / PE, PET / Al / PE, etc.

Anti freezing roll film: common ones are NY / LLDPE and PET / LLDPE (special note: PE has anti freezing function)

High temperature retortable roll film: must withstand 121℃ high temperature for 30 minutes. Common are: NY / RCPP, PET/NY/RCPP , PET / Al / NY / RCPP.

Special property roll film: high barrier / high temperature retortable roll film, which is used to packaging ham sausage, pot-roast eggs, etc., with a shelf life of more than 12 months. Common materials: PVDC, EVOH, RCPP.

Pinhole packaging film: it is mainly used for the packaging of vegetables, melons and fruits, and the price is economical.

Net roll film: packaging agricultural products , such as potatoes, onions, etc.

3、Classification of automatic packaging machine:

3.1. Horizontal from fill seal machine (HFFS)

3.2. Vertical from fill seal machine (VFFS)

LIBOPACK has many years of cooperation experience with many local automatic packaging machine manufacturers. After you order the packaging machine, we can provide free flexible packaging film to test the machine on site. During the test process, we can improve the details according to the needs of your products, Only after successful commissioning can smooth production be guaranteed. Our service aim is to completely solve the problems that will arise in our production workshop as far as possible, rather than let the problems appear in your production process.

Of course, if you haven’t decided which machine factory to cooperate with, we can provide you with suggestions for your reference, because we have many years of experience in cooperation with machine factories.

4、How to choose the material of flexible packaging film?

It all depends on your product. For example, candy can use ordinary transparent material OPP / CPP. It is enough to leave a window during printing, which can save cost. If you use OPP / CPP to package coffee, there will be a problem. The barrier of the material is not enough, and the coffee will be damp and deteriorate—-

If you are worried about how to choose flexible packaging film, please call or send E-mail to us, LIBOPACK can provide free consulting services, at the same time, can quote for your reference, of course, you can also choose the most appropriate price and the most suitable supplier, you do not have to apologize for this, we respect your choice, There is an old Saying in China –If business doesn’t work out, we’ll be friends !!!

5、5.flexible packaging film VS other shapes packaging bags:

5.1 You don’t have to worry about the comparison between barrier and heat sealing. The heat sealing equipment of automatic packaging can solve this problem. In addition, the barrier of flexible packaging film depends on the material structure and the strength after lamination.

5.2 In the product display, the flexible packaging roll film can certainly not surpass the stand up bags or quad seal pouches.

5.3 In terms of cost: the production cost of flexible packaging film is unmatched by other packaging bags. The flexible packaging film uses the automatic packaging machine and save cost.

6、What is the minimum order quantity of flexible packaging film?

Traditional gravure printing : start 300kg.

Digital printing: start 200pcs.

7、Can we get free samples of flexible packaging roll film?

Certainly. LIBOPACK usually provides non printed roll film samples to test your automatic packaging machine.

8、What is the outer packaging of flexible packaging film?

Outer packing method of roll film: Cover a PE film on the roll film, Use the export carton.

LIBOPACK has more than 20 years of experience in the flexible packaging industry. The flexible packaging film produced by LIBOPACK has quality assurance and first-class service.

We have maintained long-term cooperative relations with many automatic packaging machinery factories. In the cooperation, we have overcome many technical problems. We can proudly say that LIBOPACK’s flexible packaging film is very suitable for automatic packaging machines.

Chapter 1. Material structure of flexible packaging film

The material structure of flexible packaging roll film is generally 2-3 layers, and there are also single-layer or 4 layers of materials.

Single layer material: OPP (single side heat seal, double side heat seal)

2-3 layers of materials: PET / PE, OPP / CPP, PET / VMPET / PE, PET / Al / LLDPE .

4 layers of material: PET/AL/PE ,PET/AL/NY/RCPP,PET/AL/PVDC/RCPP。they are high barrier materials .

Chapter 2. Requirements of automatic packaging machine for flexible packaging film

2.1.roll film diameter: no more than 40cm.

2.2.roll film weight: no more than 20kg.

2.3. Inner diameter of paper core: 3 inches.

2.4. foll film thickness: 80-100 microns.

In special cases, the thickness of high barrier material with 4-layers structure may reach 120-140 microns, so the heat sealing die of automatic packaging machine is required to be specially customized, otherwise the heat sealing effect will be affected.

Chapter 3. High barrier/retortable packaging roll film

3.1. high barrier/retortable packaging roll film , It is divided into Top film and Bottom film.

Structure of Top film: SCPP/PVDC/RCPP , BOPP/PVDC/RCPP ;

Structure of Bottom film : SCPP/PVDC/RCPP , RCPP/PVDC/PE.

3.2. The Bottom film is heated and deformed on the automatic packaging machine, which is very close to the shape and size of the product. After cooling, put the product on the Bottom film, and then seal it with the Top film.

3.3. After high temperature anti-pressure sterilization, combine sterilization and microwave sterilization, store at room temperature of 25℃.

Conclusion

LIBOPACK has more than 20 years of experience in the flexible packaging industry. Our products serve the food and non food industries. With first-class quality and all-round service, LIBOPACK has customers’ love and recommendation.

LIBOPACK has maintained a good cooperative relationship with many machinery factories for a long time. We are committed to solving all the problems in the field of automatic packaging.

LIBOPACK‘s flexible packaging film has irreplaceable cost advantages. Don’t hesitate, please contact us directly.

LIBO Packaging

√Professional team both in production and R&D .

√ The excellent high quality Standing zipper plastic bag food packaging bag supplier in the world.

√ The largest high quality non-adhesive tape supplier in the world.

√ Sound capital foundation, international advanced management system.

√ Professional packaging supplier and quick response, delivery on time.

√ Innovative ,Pragmatic, Collaborative development conducting philosophy, Built solid base for LIBO of leaping future.

Professional production: Auto-packaging Plastic film ,Compound packing bag, Plastic roll film, Kraft paper Pouch,Vacuum bag, Aluminum foil bag, Spout pouch and Shape bag etc.

If you are interesting our company new products catalog also .Please help to contact with us soon !!!

(24*7 After Sales Services) Then We will offer more competitive products price for you in time .

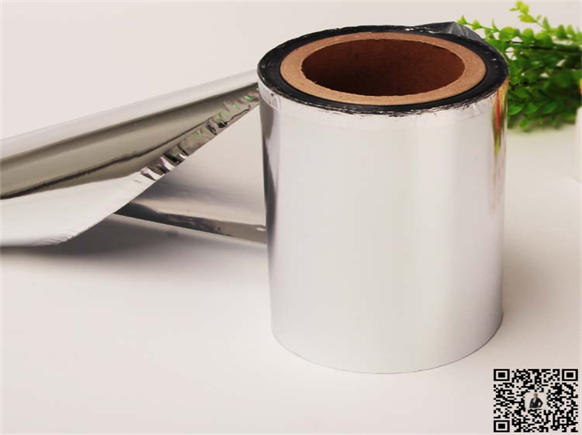

Unprinted flexible packaging foil film

Unprinted flexible packaging foil film is mainly used for the inner packaging of products. It doesn’t print.期It’s moisture-proof and oxygen-proof. At the same time, the metal aluminum film can effectively block the indoor and outdoor light damage to the product, maintain the freshness and flavor of the product. The materials used are food grade.

Aluminized foil flexible packaging film

Aluminized foil flexible packaging film most obvious characteristic is the high barrier performance, because of the use of aluminized film, and then after laminating with other materials, barrier can be greatly improved, can package some dry food or powder chemical products, medical supplies, etc..

Aluminized foil flexible packaging film

Aluminized foil flexible packaging film, most of them are composed of two layers of materials with a thickness of no more than 80 microns. This is because the barrier performance of the packaging bag is enough after using the high barrier metal aluminized film, which is designed based on reducing the cost.

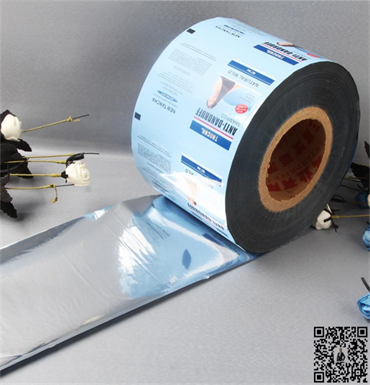

Custom flexible packaging film

The material structure of custom flexible packaging film is determined by the packaged products. For example, powdered and dry products are easy to absorb moisture, so metal aluminum must be used to improve the barrier performance, and then laminated with other materials. You don’t have to worry about the shelf life of the products at all.

Custom printing flexible packaging film

Custom printing flexible packaging film is used for automatic packaging machine. It has certain requirements for the thickness of packaging film, which is required to be 80-100 microns. This is not only to ensure good heat sealing effect of automatic packaging machine, but also to improve production efficiency. The materials used are food grade and BPA free.

Costom printing flexible packaging film

Costom printed flexible packaging films are also often used to package coffee. Based on the need of coffee powder for the barrier performance of packaging materials, three layers of materials are generally designed with a thickness of no more than 100-120 microns. PET/VMPET/LLDPE, PET /AL/LLLDPE .

Flexible packaging roll film

Flexible packaging roll film is an ideal packaging material. They can perfectly show superior performance on the automatic packaging machine: fast operation and cost saving. In LIBOPACK, you just tell us the products and requirements, and we will design the most cost-effective scheme for you.

Flexible packaging foil film

If the flexible packaging foil film is used to package powdery products, the material composition is generally 3 layers, and the bottom material PE must be pollution-resistant and easy to heat seal, otherwise, the heat sealing effect will be affected and the product will leak.

In LIBOPACK, we have special PE materials that can solve this problem.

Digital printing flexible packaging film

Digital printing flexible packaging film is mainly to try to promote new products. It is customized, small batch, copper plats free, cost saving and fast delivery. These irreplaceable advantages can make your dream come true.

In LIBOPACK, we have a professional design team and look forward to your order.

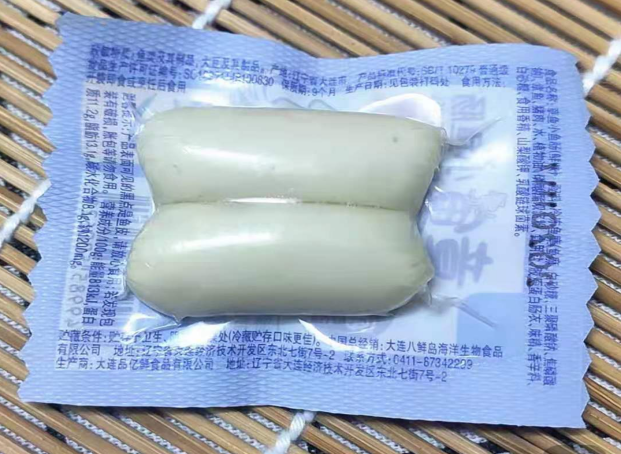

Flexible packaging retortable film for food

Flexible packaging retortable film for food , It is necessary to ensure that the packaging bag will not break and leak under the high temperature of 121℃, which requires the following two points: 1. Good lamination strength and high barrier ; 2. The heat sealing is firm, which completely depends on the heat sealing performance of PE.

Flexible packaging film for ice bag

Flexible packaging film for ice bag is also often used for food retain freshness and medical cooling during long-distance transportation. It is generally made of two layers of materials, PET / LLDPE. The materials must be soft but not hard in the frozen state, giving people a comfortable feeling.

Flexible packaging barrier film

Flexible packaging barrier film has high barrier property. After lamination, it can effectively against oxygen, moisture and UV light. All materials are food grade and BPA free.

You can customize the size and quantity. We have traditional gravure printing and the latest technology digital printing.

Digital printed flexible packaging film

In the flexible packaging industry, digital printing plays an important role, so you don’t have to worry about a small number of samples. There are 24 kinds of digital printing colors, which can change colors and patterns at any time. personalization is prominent, and consumers are encouraged to actively participate in sales activities. It is an ideal choice for brand promotion and marketing.

Flexible packaging film for food

Flexible packaging film for food is used in automatic packaging machines. The friction coefficient on the roll film surface determines the production speed and the qualified rate of finished products. Generally, we need to understand the product requirements. Of course, the most reliable method is to test the roll film sample first.

Matt opp flexible packaging film

It is widely used in the food industry. If the product is dry and fragile, it needs to use aluminized film or metal aluminum materials. It is necessary to ensure that the packaging bag can be nitrogen-filled, which can prolong the shelf life of the product. At the same time, the packaging bag filled with nitrogen can swell and protect the product from damage due to external pressure.

Flexible packaging film for food

Flexible packaging film for food is often used to package some powdery and granular food. They can perfectly cooperate with the automatic packaging machine to complete this series of work. The materials are food grade and BPA free, which can effectively locks out moisture & air and maintain the best freshness.

Digital printing flexible packaging films

Digital printing flexible packaging films is loved by variety of industries because of its low cost and fast delivery. It can be used for food and non food packaging. You can customize printing patterns, design size and quantity unlimited, reduce inventory as much as possible, and let you easily develop the market.

Flexible packaging digital printed film

Flexible packaging digital printed film can perfectly achieve no copperplate printing and save costs. However, the material structure still needs to be determined according to the characteristics of the product. You can tell us the detailed product information and we will design a reasonable packaging scheme for you.

High barrier flexible packaging film

High barrier flexible packaging film is commonly used to package ham sausage, pot-roast eggs and other foods. These foods need high barrier materials to block moisture, oxygen and UV lights, so as to prolong the shelf life of products. common materials include PVDC, EVOH and RCPP.

High barrier flexible packaging film for food

High barrier flexible packaging film for food is inseparable from two points: 1. High barrier performance, blocking oxygen, moisture and UV lights. At the same time, ensure that the nutrition of the contents is not lost and maintain the original flavor ; 2. High temperature sterilization, can withstand 121℃ high temperature anti-pressure sterilization, and the product can be stored at room temperature of 25 ℃.

High barrier flexible packaging film for food

Material structure of high barrier flexible packaging for food : BOPP/PVDC/RCPP , PET/PVDC/RCPP , EVOH can also be used to replace PVDC. All materials are food grade and BPA free. Please feel free to use.

OPP flexible packaging pinhole film

Opp flexible packaging pinhole film is commonly used for the packaging of vegetables. One side heat sealing OPP is covered with neat and orderly round holes. The diameter of the round holes is the same as that pin, which can insect prevention, fog prevention and air permeability, and keeps the vegetables fresh. This material can work with the automatic packaging machine to reduce the production cost.

Opp flexible packaging pinhole film

Opp flexible packaging pinhole film has small round holes and good air permeability, so that vegetables, melons and fruits can breathe fresh air and keep fresh. At the same time, during cold storage, the internal and external temperatures of the packaging bag are the same, the packaging bag will not fog, will not block the sight of consumers, and perfectly display the storage of products.

Opp/ cpp flexible packaging pinhole film for vegetables

Opp / cpp flexible packaging pinhole film for vegetables. The materials OPP or CPP have extremely high transparency and will not affect the appearance display of vegetables, melons and fruits. At the same time, these two materials are resistant to low temperature, cold storage characteristics. They are food grade and BPA free, so they can be used safely.

Flat net roll flexible packaging film

Flat net roll flexible packaging film has an obvious advantage that the net roll is made of a special PE material. It has compact structure, insect resistance and good air permeability. It can package some heavy products such as vegetables and fruits. In addition, you can customize printed brands and product information.

PE net roll flexible packaging film for vegetables

PE net roll flexible packaging film for vegetables can be perfectly matched with the automatic packaging machine and is deeply loved by farmers and vegetable dealers. It can withstand both packaged vegetables and heavier fruits, and has good air permeability to ensure the long-term preservation of products. The materials used are food grade and BPA free.

Recyclable net roll flexible packaging film

Recyclable net roll flexible packaging film is made of a single material PE. As we all know, PE is a recyclable material approved by the EU, and the weight of the packaging bag is very light, reducing the waste of environmental resources. It is an ideal and environment-friendly new packaging material.